Principles of designing green roofs

Insulating root resistant layer

The basic requirement for roofing is plant root resistance. Single- and double-layer materials are used in the construction of green roof systems. Single-layer plastic materials (foil, membranes) are generally root resistant. Double-layer materials should have a minimum acceptable thickness of 4.00 mm for the undercoat layer and 5.00 mm for the surface layer. Both layers should be made of bitumen modified with SBS polymer. Reinforcement (the carrier insert) should be made of polyester non-woven fabric with a minimum weight of 150 g/m2 for the undercoat layer and 180 g/m2 for the surface layer. An additional protection is the use of a third layer of base roofing membrane with minimum parameters, such as the first layer of roofing membrane. The top layer of the cover should be root resistant. Such resistance is ensured by the addition of a special chemical agent or a copper foil insert. In the case of using normal polymer and bitumen roofing membranes which are not plant root resistant, it is permissible to add a root protection made of foil 0.4 mm thick with folds of min. 0.15 m. Roofing should be installed in accordance with the manufacturers' instructions and the applicable standards.

Roof penetrating elements

In order to minimize the number of joints and connections on the roof surface, the roof penetrating elements should be assembled in one place. Green roofs should be easily accessible for maintenance. Designing a water connection on or near the roof is recommended.

Preventive fire protection

Construction and insurance supervision requires that roofs made as "flame resistant roofs" should be protected against fire from above and thermal radiation. On the basis of the test methods according to DIN 4102 Part 7, the surface layers of a green roof, which fulfill these standards in the case of the specific structure, are tested. Xero Flor vegetation mats are flame resistant and meet DIN standards.

When is a green roof classified as a flame resistant roofing?

Roofs planted with intensive greenery, where it is watered and cared for, are usually made on a thick layer of substrate. Such roofs, without the need to meet any further conditions, are resistant to fire and thermal radiation from the above, which is why they are treated as a flame-resistant covering.

Roofs planted with extensive greenery, i.e. one that does not need to be additionally irrigated and which very rarely undergoes additional care, are classified as flame resistant roofs, provided the following conditions are met:

- the substrate layer is at least 3 cm thick,

- the substrate contains not more than 20% by weight of the organic part,

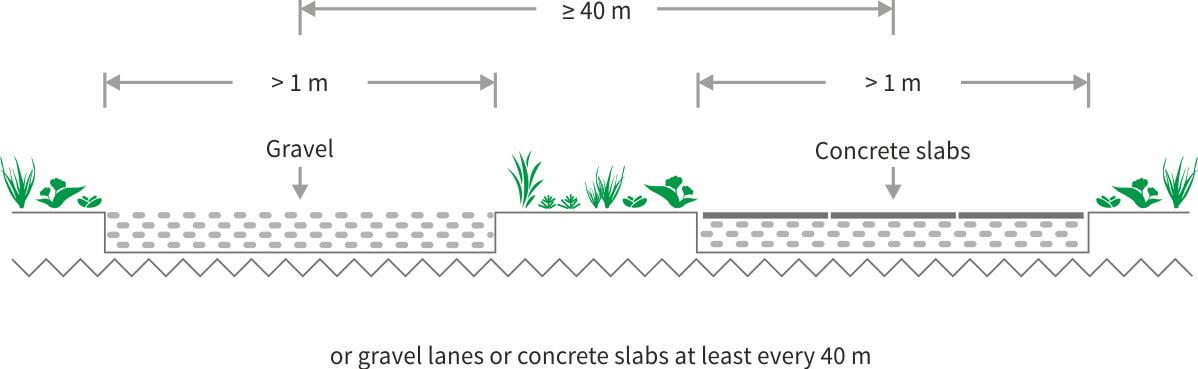

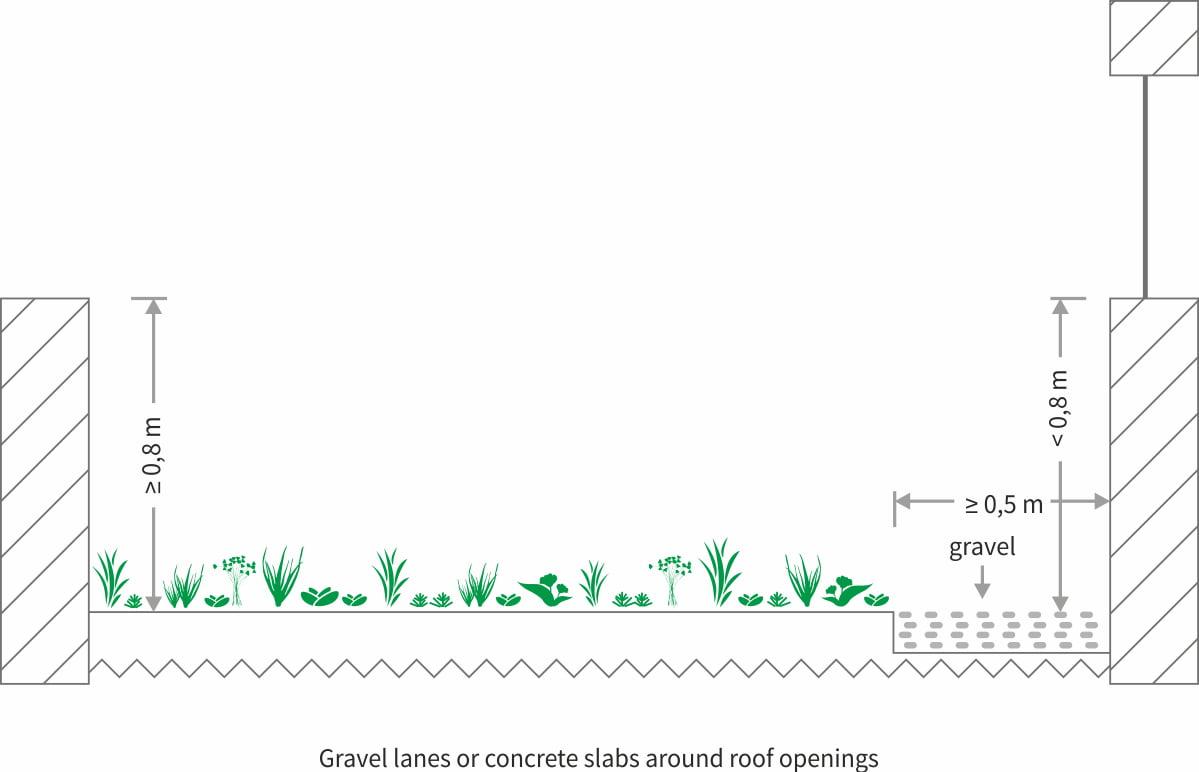

- fire barriers (e.g. from a gravel lane) are located every 40 m in the case of larger areas planted with greenery,

- gravel bands (approx. 50 cm wide) are applied in the case of openings on the roof surface (vent windows, fanlights) .

Protection against heat and moisture

According to DIN 4108, only the layers on the inside of the sealing or the roofing can be considered when calculating the thermal insulation. The green roof layers are not taken into account when calculating this parameter.

Wind uplift forces

The surface layers of greenery on the roof must remain in their places also during strong gusts of wind. The necessary additional loads are in accordance with DIN 1055, part 4. Here is a slightly simplified method of solving the above problem. In the central part of the roof, an additional load with a thin layer of substrate is enough, where it is not possible to detach the layers planted with greenery due to the wind uplift force. However, the situation is different in the area of edges and corners - places particularly exposed to wind uplift forces. In such areas it is usually necessary, depending on the roof shape and height, to use additional protective load in the form of gravel or concrete slabs.

0,5 (50)0,8 (80)1,1 (110)

| Wind uplift forces at the roof surface with a slope of up to 8o depending on the horizontal projection of the roof axb and the building height h | Height of the building from the ground | ||

|---|---|---|---|

| 0 – 8 m | 8 – 20 m | 20 – 100 m | |

| Stagnation pressure q in kN/m2 (kg /m3) | |||

| Roof area and aerodynamic pressure coefficient Cp | Pressing force (wind uplift force or required additional load in kN/m2 (kg /m3) | ||

| Dimension ratios b/a=<1,5; h/a=<0,4 Corner area Cp=-2,0 Roof area Cp=-1,0 Central part Cp=-0,6 |

1,00 (100) 0,50 (50) 0,30 (30) |

1,60 (160) 0,80 (80) 0,48 (48) |

2,20 (220) 1,10 (11) 0,66 (66) |

| Dimension ratios b/a=<1,5; h/a=<0,4 Corner area Cp=-1,5 Roof area Cp=-1,5 Central part Cp=-0,8 |

1,00 (100) 0,50 (50) 0,30 (30) |

2,24 (224) 1,20 (120) 0,48 (48) |

3,08 (308) 1,65 (165) 0,88 (88) |

| Dimension ratios b/a=<1,5; h/a=<0,4 Corner area Cp=-2,5 Roof area Cp=-1,0 Central part Cp=-0,6 |

1,00 (100) 0,50 (50) 0,30 (30) |

2,00 (200) 0,80 (80) 0,48 (48) |

2,75 (275) 1,10 (110) 0,66 (66) |

| Dimension ratios b/a=<1,5; h/a=<0,4 Corner area Cp=-0,3 Roof area Cp=-1,7 Central part Cp=-0,8 |

1,00 (100) 0,50 (50) 0,30 (30) |

2,00 (200) 1,36 (136) 0,64 (64) |

3,30 (330) 1,87 (187) 0,88 (88) |

Plant layer

Extensive greening

Extensive greenery includes plants with the lowest vegetation requirements, which are able to maintain and develop themselves. They reproduce vegetatively and generatively and do not require troublesome care (apart from the recommended annual inspections in accordance with the manufacturer's guidelines) and additional irrigation. Plants adapted to extreme weather conditions and with high regenerative capacity are used. In green roof systems, it is recommended to use local plants with minimal vegetation requirements, such as: mosses, perennials, sedum, herbs and grasses. The methods of implementation are different - from planting plants in the appropriate number per 1 m2 (from 10 to 25 pcs/m2), to laying out ready-made green vegetation mats.

Substrate vegetation layer

Extensive mineral substrate is designed to enable plants to develop properly and in special cases to fulfill the role of a ballast layer.

The composition of the substrate should consist of products of mineral origin with a small addition (max 10% by weight) of organic ingredients. It should have a stable skeletal structure that is resistant to frost and UV radiation. The air content in the substrate should not exceed 10% with the maximum water saturation. The salt content virtually should not exceed the value of 1.0 g/l of the substrate. The substrate should have an appropriate water storage capacity at the level of min. 15% by volume. Technical requirements for the thickness of the substrate layer on the green roof are limited to the maximum weight that the roof can carry. The table below shows thickness of the vegetation layer (substrate) depending on the designed form of greenery.

Retention and drainage layer made of hygroscopic rock wool

Hygroscopic rock wool is a special type of mineral wool. It is to ensure the best possible vegetation conditions for plants, using its unique features. It is used in the construction of extensive green roofs as a substrate substitute due to its very light weight and very high water retention, up to 92% at full saturation. It is therefore used as a retention and drainage layer. In the extensive system, mineral wool is dedicated mainly as a layer on which green vegetation mats are spread. When using the above-mentioned layer system, a green roof can weigh approx. 45 kg/m². In the case of planting in an extensive and intensive systems, wool should be covered with an appropriate amount of substrate, taking into account the needs of the planted plants.

Filtration, protective layer

The filtration layer should have at least 10 times greater permeability than the vegetation layer, thanks to which it will be able to protect the drainage system and drains from siltation. The filtration layer should be made of a structural non-woven fabric made of 100% polypropylene with a weight of 200-250 g/m2, free of chemical binders, characterized by long-term durability (also in terms of drainage and filtration stability) and resistance to water, chemicals and decay. The nonwoven fabric needs to have good water permeability in the horizontal and vertical directions and the ability to diffuse water vapor. The filtration layer in the form of a non-woven fabric is placed directly on the drainage, and under the vegetation layer, leaving a fold of at least 10 cm between individual bands

Drainage layer

In accordance with DIN 4095, a drainage layer is laid on the slab under the substrate, which ensures drainage of excess water, constituting an additional ballast and having a negative impact on plant development. It must be resistant to changing weather conditions (moisture, temperatures below zero) and be characterized by high mechanical strength to tensile, elongation, friction and compression. The drainage layer of a green roof must be constructed in such a way that it functions for a long time. Drainage should discharge water in the amount of 0.03 l/s m2 = 300 l/s ha. Natural drainage from rinsed gravel, applied sometimes, should have a granulation of 16 to 32 mm, and the minimum thickness is 5 cm. Drainage made of artificial materials, such as loop mats, bucket mats or geotextiles, are light and low, yet very durable and mostly meet the standards, while the geotextiles used in them perfectly filter the water, preventing siltation of the drains. It is assumed that on slopes exceeding 2o, a drainage system is not required (when using the XERO FLOR system).

Gravel layer (band)

In order to ensure good communication and access to technical devices installed on the roof around the roof edge (attics and adjacent facades of higher parts of the building) as well as technical devices (fans, culverts, skylights, smoke vents, control chambers), a band of rinsed gravel with a fraction of 16-32 mm and a thickness of approx. 10 cm should be made. The width of the gravel band should be at least 50 cm.